LEDs have been around for over 40 years and some people are still afraid of them. LEDs come in many shapes sizes and colours. The big advantage for us modellers is that they do not generate heat (no damage to the plastic shells) and are very forgiving of voltage variations. A 1.5 volt lamp will blow at 1.52 volts.

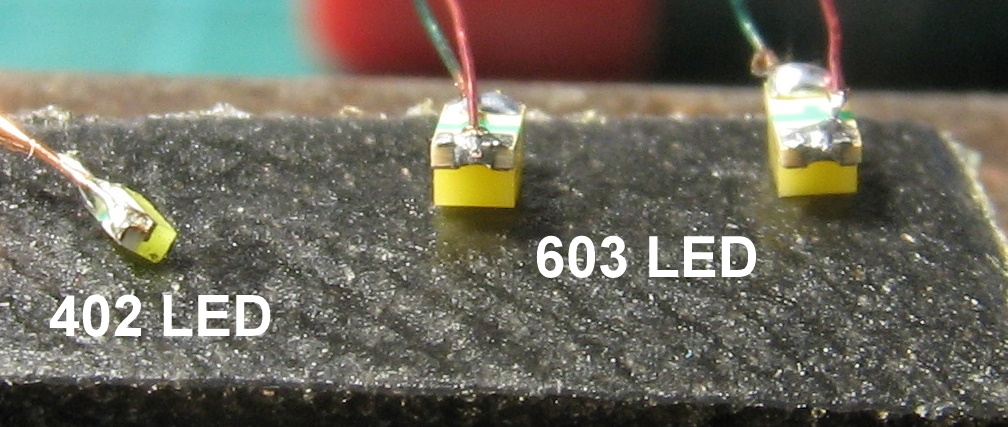

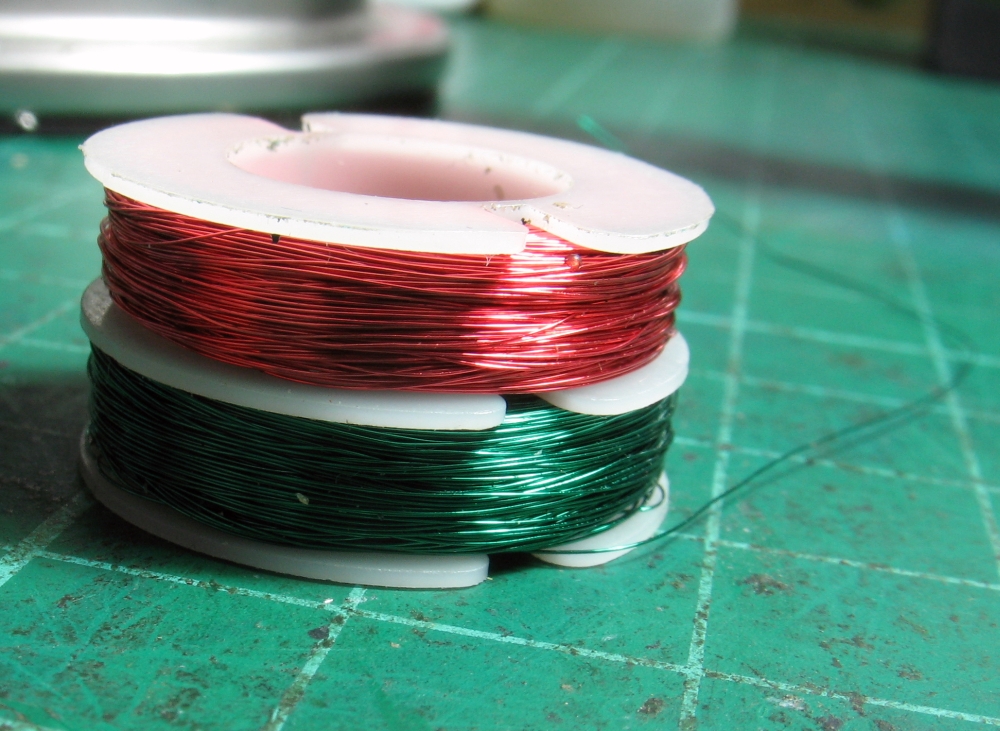

This photo shows the difference in size between a regular 3mm LED and a 603 surface mount. They are available in white, warm white, sunny white, golden white, red, green, and orange which are suitable for our needs. There is also a bi-colour version (two colours) with a common anode for use with decoders. All the surface mount units for model railroad use can be purchased with leads attached. The leads are 150mm long and the longer of the two leads indicates the Anode or positive end. This connects to the blue lead on a decoder.

I am going to show you how to connect the leads to a SMD LED yourself. This saves the labour cost involved with units with leads attached. After doing the first 50 they become easy - trust me. The 603 is the easiest to use and easiest to obtain. Leave the 402 for a later date - maybe.

You will need a fine tiped soldering iron – temp controlled to about 280 – 300C. Rosin core solder 60/40 and 0.71 mm diam. This is the solder you would use for all your normal model soldering.

A good iron cleaning station that looks like a Brillo pad – available from Dickie or JayCar. The most important other tool is Flux – not the thick paste you get from your friendly plumber but a good liquid type designed for modellers. I use Carrs Orange or Yellow for all electronic type work. Sources for Carrs (from the UK) are In Australia – and – In the USA

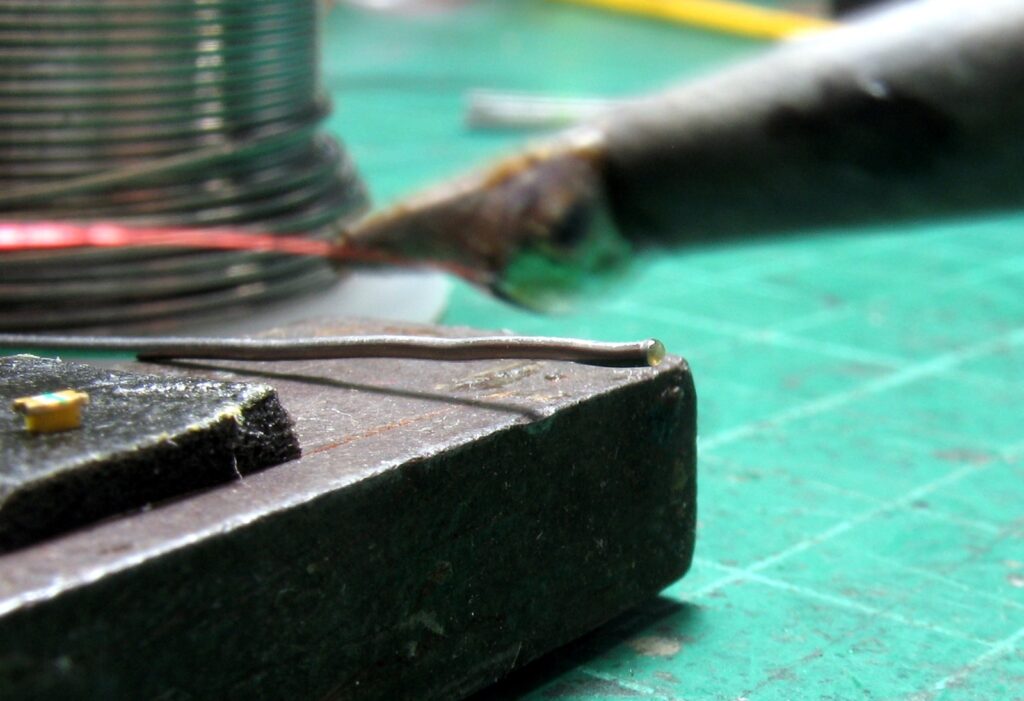

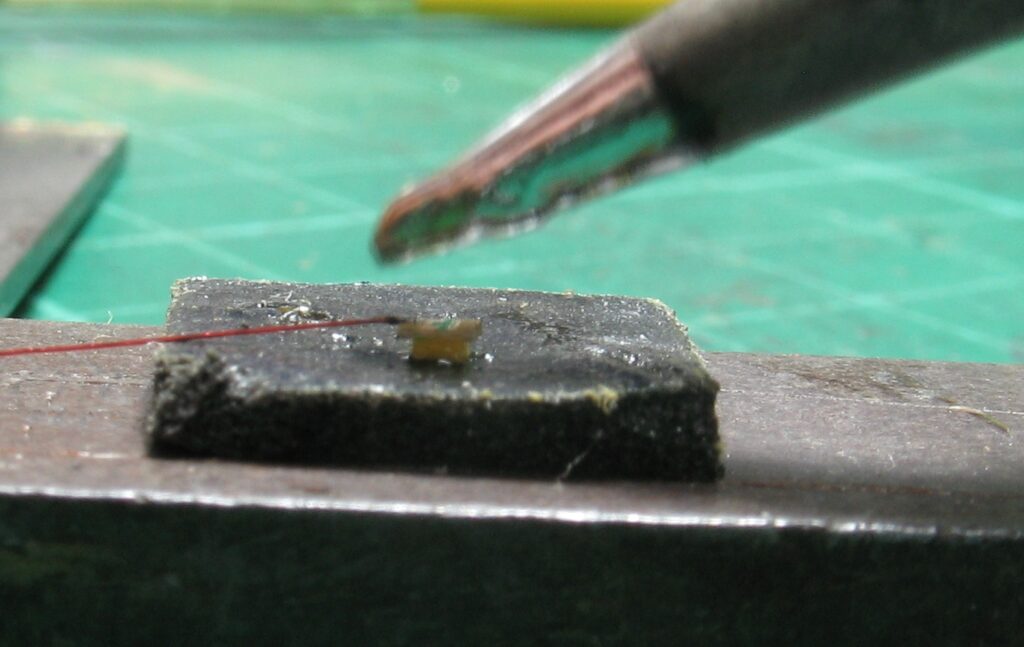

Step One Mount the LED on a small piece of double-sided sticky tape. The tape needs to be on something firm – I use a steel 2″ square as shown.

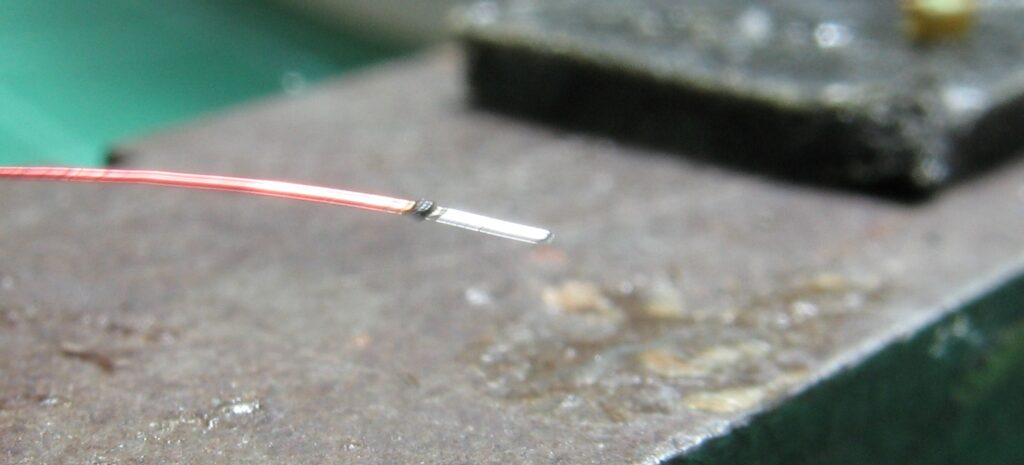

Step Two We need to remove a short section of the enamel from the wire so that we have enough good tinned wire to solder to the LED.

Step Three We now apply some flux to the back of the LED with a small brush. With this done we can now attach the first wire to the LED. Hold the wire on the gold section on the end of the LED and lightly touch with the iron. The flux will help to bond the wire to the pad instantly.

I use a small battery powered unit – a “must have” tool is you are using any LEDs. You will need to tin the ends of the wire as you did for the other end. I normally use leads about 2″-3″ long. I am not sure where you would get one in the USA, but this site In the USA shows you the unit.

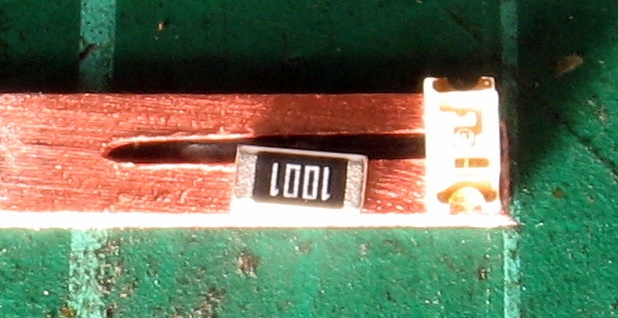

Here I have connected the LED to the 10 ma connection on the tester. Now to allay some of your fears. An LED will normally run on a 12 volt DC supply and require a resistor of 470 ohms to limit the current to 20 ma. Using a 1k0 resistor, (1000 ohms) will limit the current to 10 ma and I guarantee you will not see the difference when connected to your decoder. This will also mean that the LED is safe up to 24 volts and I only know one system that exceeds this level.

Where to use them

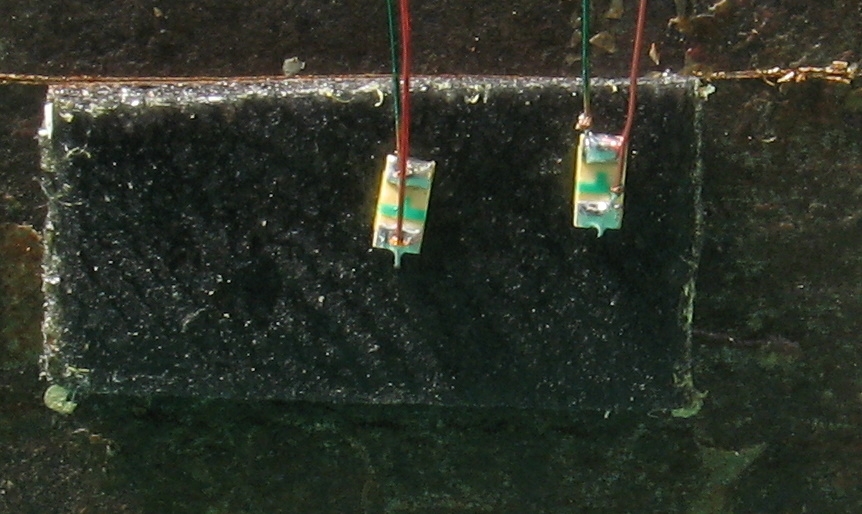

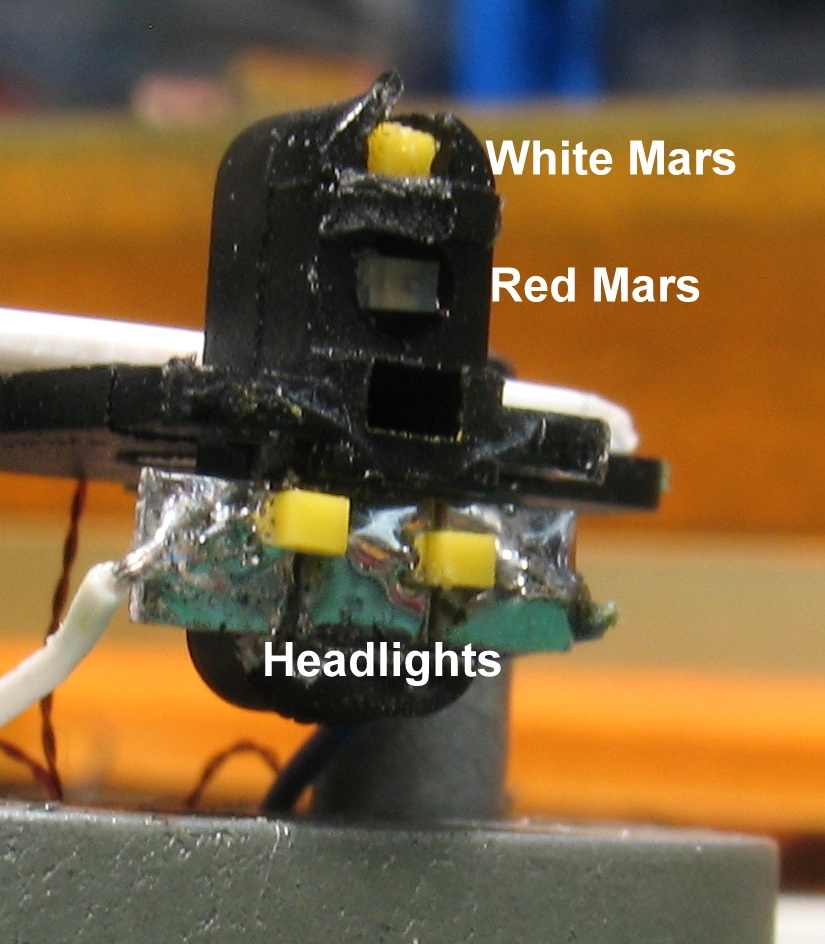

These two photos show them mounted as markers. Part of the cast on lamp housing has been removed and the SMD glued in place and painted black. In these cases, the 2 LEDs have been connected in series with a 3k6 resistor in between.

The loco is a NSW 35 Class from Austrains. It has QSI decoder for sound and a TCS FL4 for the lights.

Not shown here is the cab light.

The head light is also an SMD LED but that is factory fitted.

All finished and working. The head light is filled with Microscale “Crystal Clear” to seal the LED and prevent movement. The light here looks a little too bright for a steamer – that is just the photo, but if you wish to “tone down” the light then just add a coat of paint – normally Tamya’s Clear Orange.

The next part

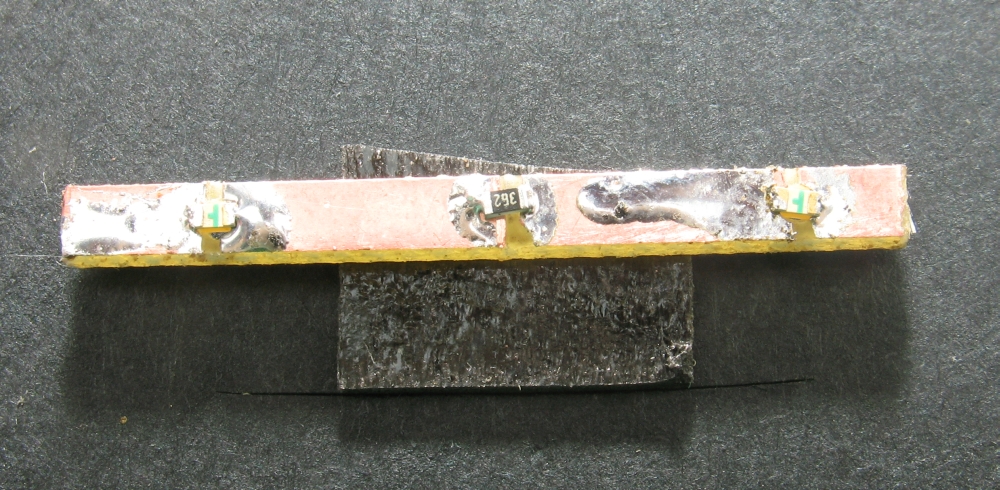

Next, is mounting these little babies on a small piece of circuit board such as a piece of Clover House Sleeper (tie) with a surface mount resistor.

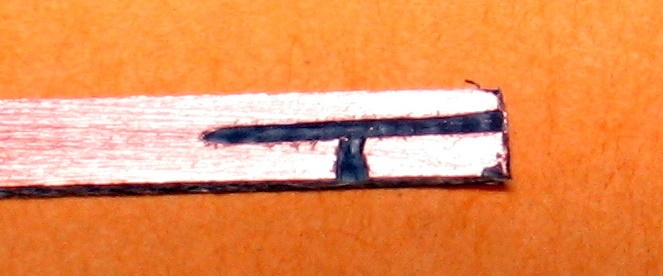

Step A involves wiping the piece of pcb with the flux brush. You will see the colour of the cladding change as the flux removes the oxidisation. Then file a small slot across the pcb.

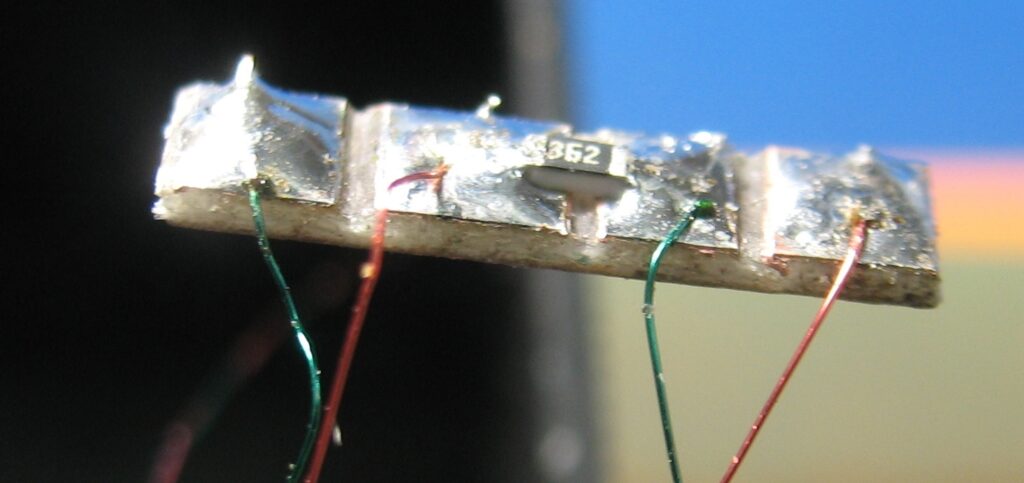

Step B The LED will sit across the slot as shown (this is actually a resistor). You then touch the pcb next to the LED and the solder will immediately run under the LED. Then do the other side of the LED.

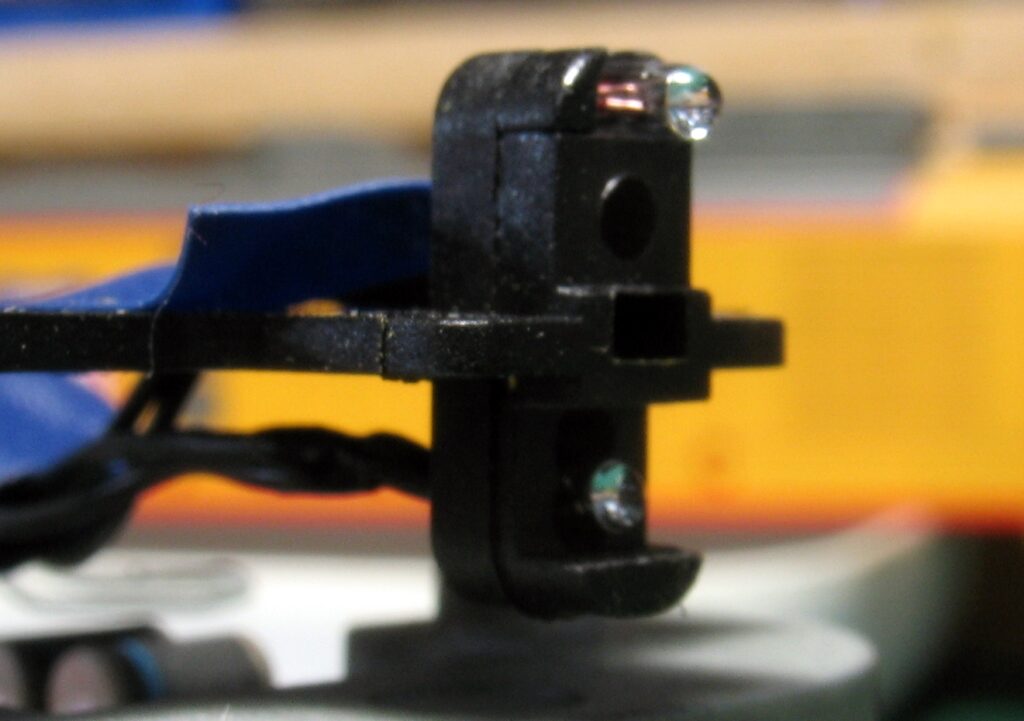

The next two photos show the Athearn Turbine lamp housing. The first is “as is” with 2 x 1.5 volt lamps they are not very bright and any voltage spike will blow them, if the resistor is changed to make them brighter then they could get too hot for the plastic body.

So, how to achieve these effects

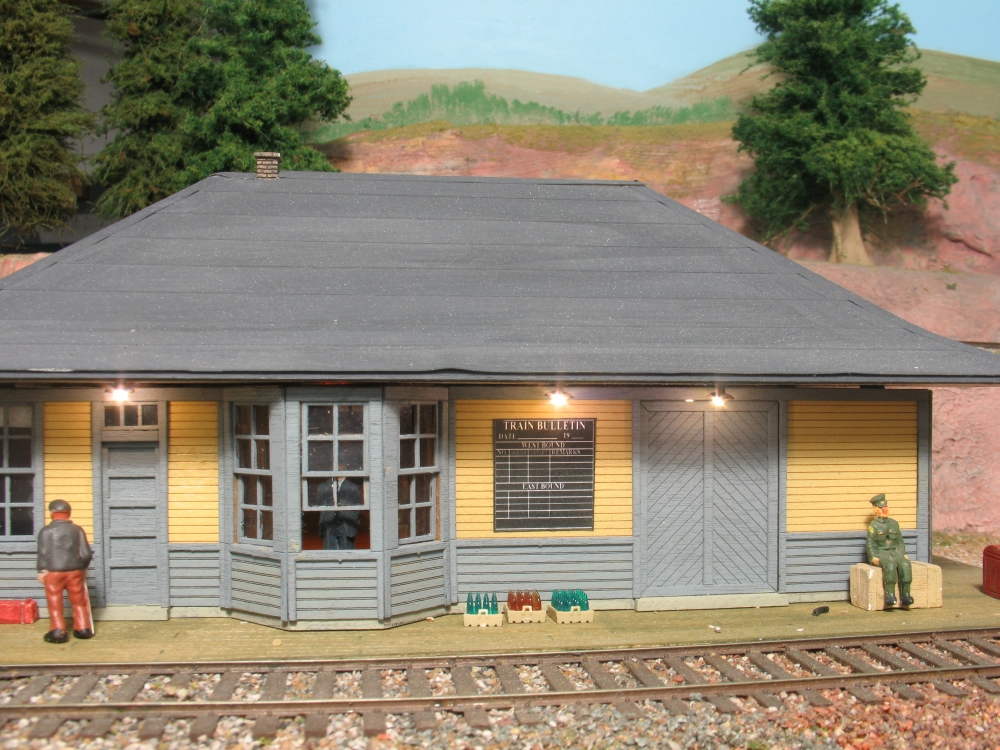

A few shots of things on my layout using fibre optics and SMDs

The possibilities are endless and the results satisfying

If you have fears of one side of the LED touching the shell of the brass of a loco, then use a 1k2 resistor on each side of the LED. If either side touches the shell there is a resistor between the shell and the decoder.

If you have an LED at the front of a loco or only have room to run a single wire, then connect the Anode ( + ) to one of the track pickup wires, or if it is a split frame then to one half of the frame instead of to the blue decoder wire. This will also drop the voltage to the LED by about 35%.