Gerry Hopkins MMR

The Lima XPT requires some extra work to make it a reliable runner. There is nothing we can do about the “pizza cutter” flanges but we can get it run well.

The first and most important thing to do is replace the “motor”. The normal method is to replace the armature with the complete replacement motor from Model Torque.

The photos and text below will show you how to add pickups to the power car and to the following coach.

This photo shows the power car and the leading coach. This unit has been fitted with a Soundtraxx DSD101LC sound decoder with EMD 2nd Generation sound ($65AU)

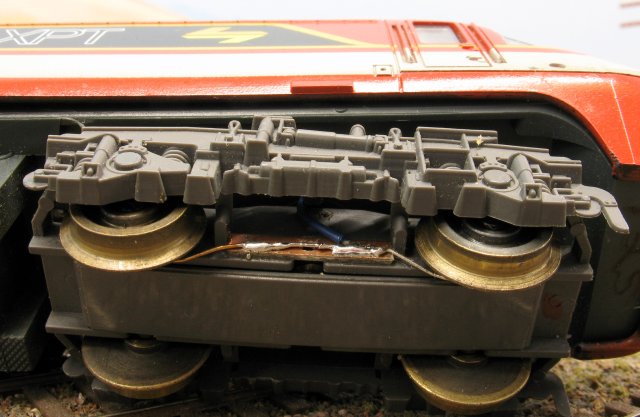

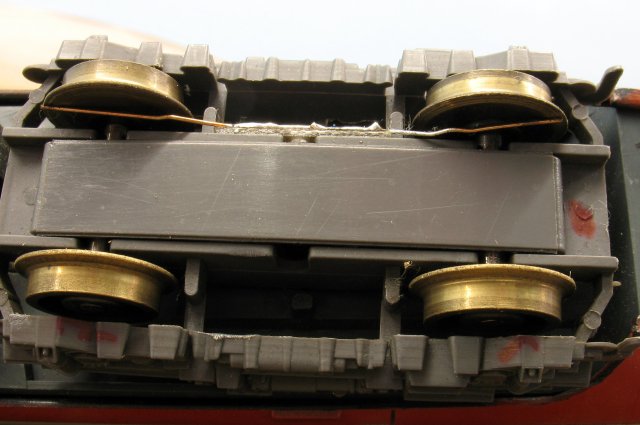

Here you can see that I have added a small piece of PC Tie (Printed Circuit Board Sleeper)to the side of the truck. Attached to this is a piece of 0.012″ Phosphor Bronze wire. This is connected to the decoder through a small hole drilled in the floor power car.

Small flexible cable is easy to find – strip the tail of an electronic rodent (old computer mouse). Do the same on both trucks. Paint the PCB when you are finished – you will never see the extra pickups

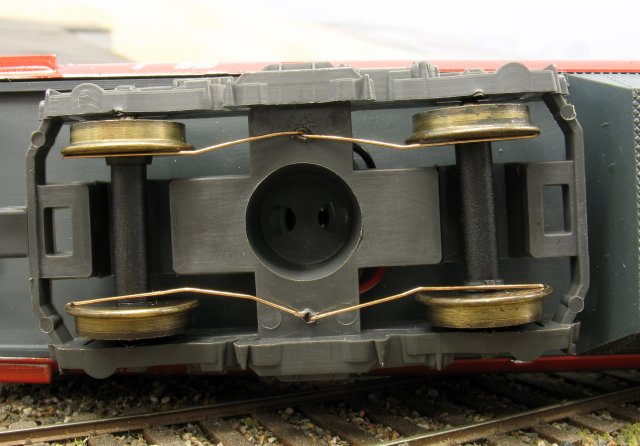

This shows the pickups fitted to the coach. The Phosphor Bronze wire should touch the outer rear edge of the flange. Yes, it will wear out – after approx. 500 hours. Solder a length of fine, flexible wire to the small tab on to of the truck and feed up into the coach. Do the same for both trucks and join inside the coach.

Headlights switched on ready to go. The units run a bit noisy on my code 70 track (will not run at all on code 55). They crawl at 2-3 kph over my dead frog turnouts without any problems. The owner, a friend of mine (I do have a few, they don’t cost much) uses code 100 Peco rail so he has no problems with them.