HO Proto 2000 Diesel Locomotives

Diesel with 4-wheel trucks (Clicking Noise – Split Gear)

Text by Ron Solly

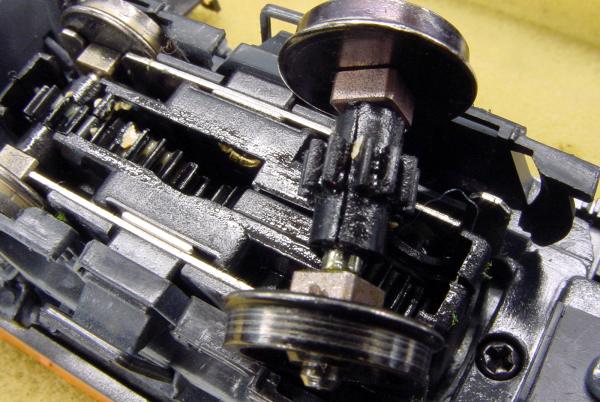

While these locos are good value, they have a common mechanical problem. After some running & things get warm, the plastic gears on the axles tend to either split or break into a couple of parts.

If they split, the cog/teeth widen & the result is a clicking noise as the gear rotates & it may cause a slight reduction in pulling power. If a noise is heard from the bogie, remove the wheelsets & most of the time, by twisting the wheels on the axles they rotate easy to each other.

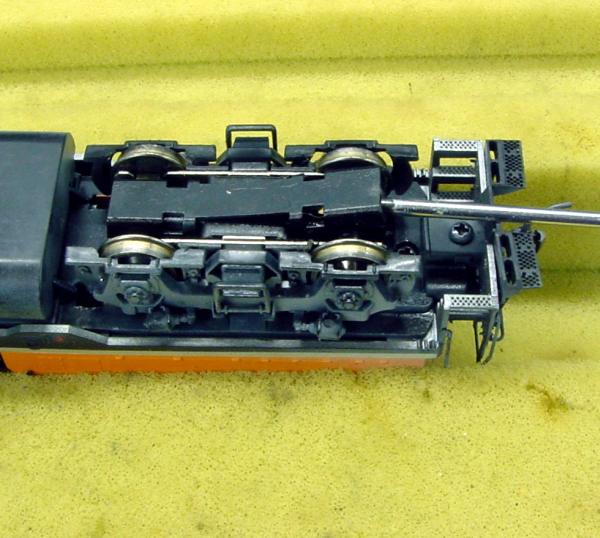

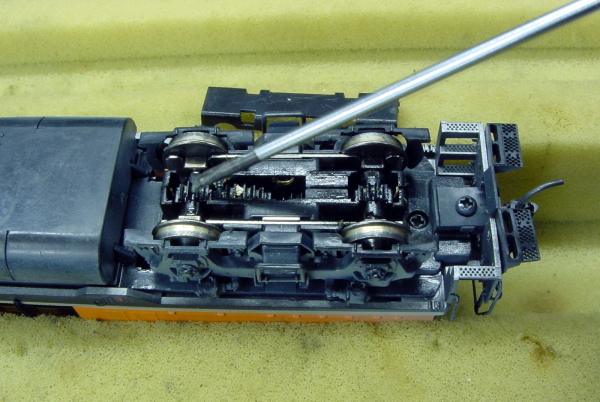

Remove the bottom cover of the truck as shown, be gentle and the cover will pop off.

But if parts come off the gear, it can allow the wheels to change gauge & in the worse case, allow the metal axles to come into contact with each other & bingo, a short circuit. It took me about one hour of basically pulling the motor, etc to pieces before I found the fault. Not having replacement wheelsets on tap. I quickly separated the axles by using a grey Kadee fibre washer as a temporary stopgap.

The break can be on either axle.

As Lifelike mechanisms are almost identical to Athearn, especially in the drive wheels, a replacement using Athearn is the final fix. It seems that the plastic in the gear is more substantial than that used by Lifelike. The only problem is getting the Athearn wheelsets – they are scarcer than rocking horse manure. Lifelike is usually easier & cheaper to obtain – depending on the wind direction on the day you try to order.

The split gear can be seen here. Before fitting the replacement wheel set, check the wheel gauge with your NMRA Gauge.

Diesel with 4-wheel trucks (Poor Running – Jerky Running on DCC)

If you take a close look at the underside of the trucks you will see that the phosphor bronze bearings slide up and down in the metal side frame. Because of the very loose fit, the constant voltage of DCC causes corrosion between the bearings and the frame.

There are 2 fixes, the first is to use a contact cleaner such as Electrolube, CRC 2-26, and Rail Zip to clean the contact surfaces. Oil will not work very well for this.

The second is to solder a small flexible wire to each bearing and then connect the other end to the side frame.