Fitting Pickups to Brass Locos for Reliable Running

Brass locos are built to be displayed on glass shelves, but, a few people like to run them on a layout. The problems start here. The locos do not normally have a flywheel fitted to the drive shaft or motor. They have minimal pickups to get the power to the motor.

Now, we want to fit decoders to them, not just decoders but SOUND decoders. Any slight hiccup causes the sound to drop out – which we notice immediately! There are two ways to get around this first fix the original problem by adding pickups that work and secondly modify the decoder to mask the problem. Ideally, you can do both of the modifications for perfect running in all conditions.

You can get great help with the decoder modifications at Marcus Ammann’s – Main North Webpage.

For the addition of pickups – read on.

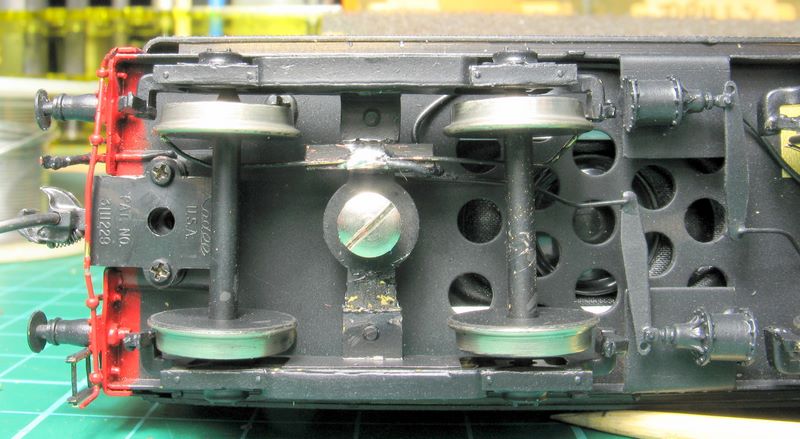

The first loco is the Mansfield’s Streamlined 38 class. This loco is typical of most brass locos in that it picks up from the right side drivers on the loco and the left side wheels on the tender. The wires run straight to the motor. To fit a decoder we remove these wires and replace them with the decoder wires. Orange to one brush and Grey to the other brush.

This shot shows the underside of the loco. Two small pieces of circuit board have been glued to the bottom of the chassis as shown. The circuit board is a section of a PCB tie from Clover House. The wipers are made from phosphor bronze strip only 6 thou (0.006″) thick and 2mm wide (0.080″) and is soldered to the PCB. You can run a wire from the PCB straight to the insulated draw bar terminal.

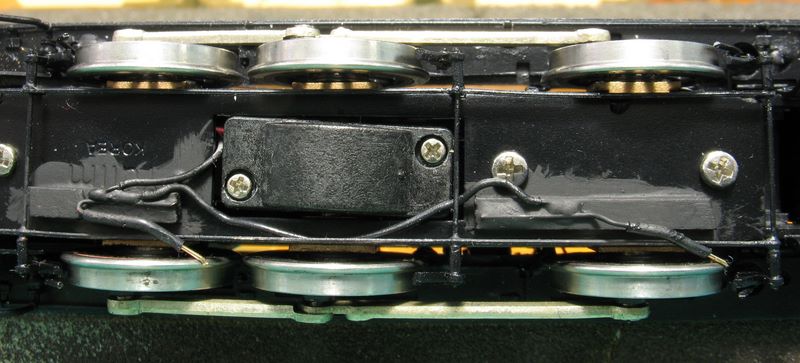

This is the rear truck on the tender. The PCB has been glued to the underside of the truck cross member and a 12.5 thou (0.0125″) phosphor bronze wire soldered to the PCB. the wire is bent to rub on the back of the flange – only set a light pressure so the wheel can still turn. Do the same on both trucks.

The same system was applied to this NSW 19 class loco. If the decoder is in the tender, run the wire up into the tender and join to the Red wire from the decoder. Also run a wire to the frame of the loco. The decoder in this loco is mounted above the motor in the firebox. so a wire was run from the tender to a small socket soldered directly to the loco.

This just shows the relative size of the 19 class against a P2K 0-6-0. Although a TCS M1 was mounted in the loco of the 19 class, a Tsunami Micro would fit in the tender with a small speaker

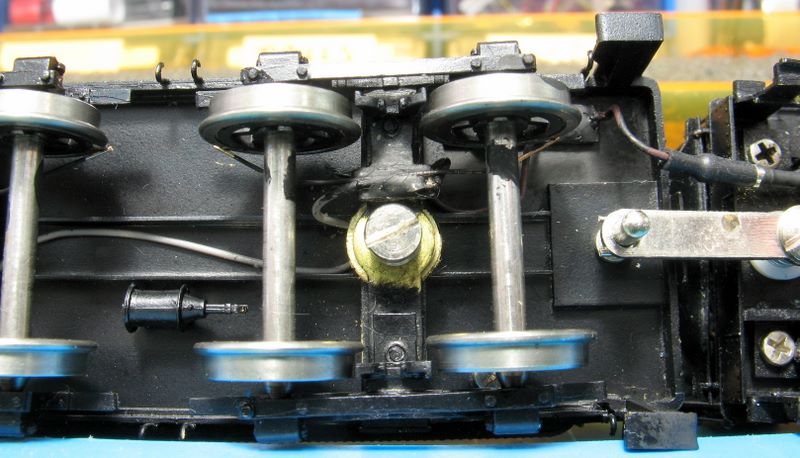

This is the underside of the 19 class. The same system was used for mounting the pickups but this time 12.5 thou wire was used and a small piece of insulation was added as the wire went very close to the brake rigging.

In this shot you can also see the small connector in the top right hand corner, this goes to the red wire of the decoder. Also make sure the surfaces between the trucks are clean and are not painted!

This is the other end of the spectrum, but just as big a challenge. This AD60 Garrett has the Tsunami in the boiler with the speaker in the cab pointing down.

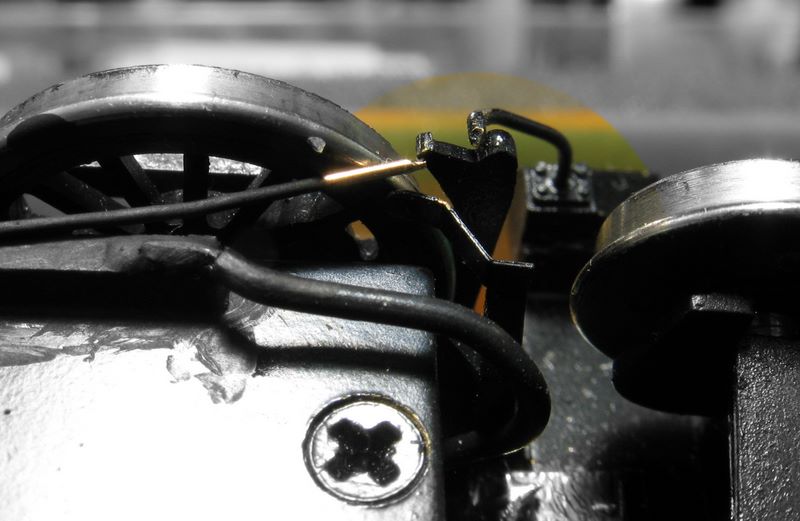

You can see that a single piece of PCB was used here with wire for each wheel. Both the engine units were setup like this. The loco is powered by 2 can motors and only pulls 160 milliamps when running with 8 x 40″ cars.

If you look closely at the ‘new’ contact you can see there is a small contact just below it – there were four of these contacts for the 8 x drivers down the one side of the loco. Major shorts did occur at the beginning but these were caused by bent brake assemblies on all the trucks.

I run the locos around the layout for a good 30 mintes before setting up the right sounds and performance. My layout has 30″ radius curve – tight for some brass locos. It also has 2% grades and most of the turnouts are hand layed and have dead frogs. This one is code 55 and is spot on for NMRA standards.

This is a Micro Engineering Turnout, also with dead frog. The pickups allow the locos to run perfectly all over the layout without any hiccups. One day I may get a loco that needs the “Electronic Flywheel” but after fitting decoders to at least 300 brass locos I have not needed one yet.