The SD7/9 locos from Proto 2000 are smooth running, quiet locos. However, after a few hours of running they can get erratic due to the pickup design. Below is the procedure I use to combat this. My locos have decoders for DCC and they are programmed for a top speed of 35 mph and do a lot of low speed switching.

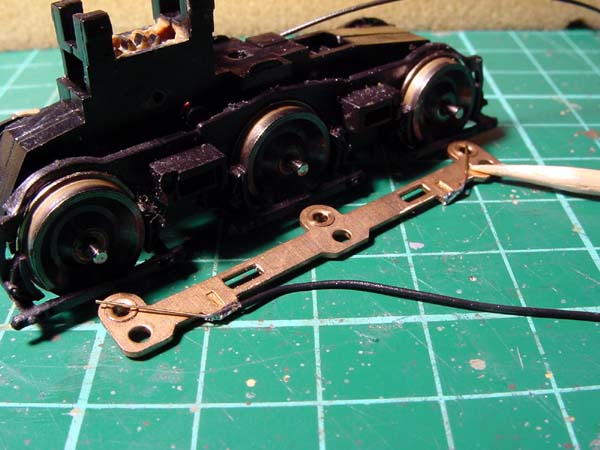

Remove the trucks from the loco and then remove the side frames. The photo shows how the contact bar sits on the axle extensions. The wires to the decoder are just spring clips.

With the side contact bar removed we can add extra pressure pickups to the axle extensions. I use 12 thou (0.012″) brass wire, why this size? – Because I have plenty – I use it for hand rails and other detail parts. 10 thou brass or phosphor bronze would be just as good. The wire will wear out after about 10 years of very heavy use but is still worth the effort.

Clean the area to be soldered with a small file and then tin the surface (Tinning – heat the surface and apply a small amount of solder, the flux in the solder will clean any oxidants from the area). Also tin 3mm (1/8th inch) at the end of the brass wire, this will ensure a good bond to the contact bar. Solder to the bar as shown and bend downward across the axle hole and cut to length as shown.

Solder the flexible wire, that connects back to the decoder, to the same location as one of the wires. I always have plenty of wire left from decoder installs – they always supply a good length. Refit the side frames making sure that the wire sits on top of the axle as shown. My locos have sound decoders fitted and soon show up any pickup problems. I did this modification to the SD9 and then ran it at low speed all over my system for an hour without a glitch.