Turnouts are the least understood of the items associated with model railways and to compound the problem upgrading to DCC has brought more misunderstanding. There are many very good web pages on all the variations of the different brands so I will only give a few of the basic tips with the help of detailed photos.

The term DCC friendly means many things to many people. There are two main points of view – the powered frog and the dead frog.

The powered frog has its electrical polarity changed to match the route through the frog, this can be done by the contact of the moving point rail against the fixed stock rail. The alternative is to use the contacts on a separate switch; either a slide switch, micro switch or turnout motor.

The dead frog (sorry Kermit) is electrically isolated from the rest of the track. The benefits of this are; no extra switches or contacts, no extra wiring, no climbing under the layout to fix or replace the extra parts.

Most modern (made in the past 15 years) locos have pick ups on all the wheels (The Italian brand is/was the exception) so passing over a 1″ piece of dead rail is quite acceptable. My HOn30 locos are quite happy with dead frogs as are all the standard gauge locos.

Below are a few of the common tips for electrical and mechanical problems to help get your layout working.

Peco

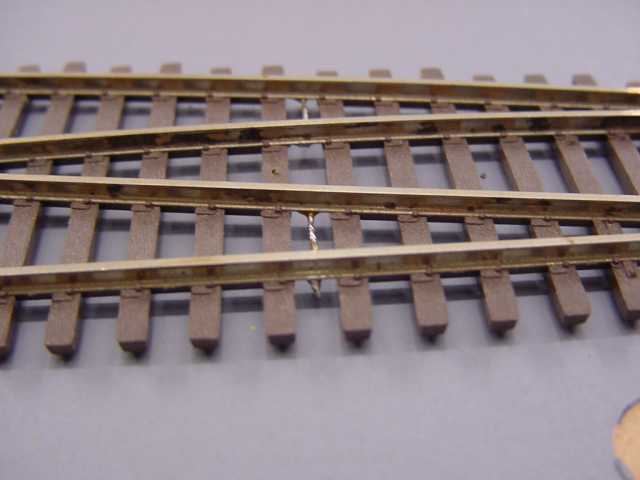

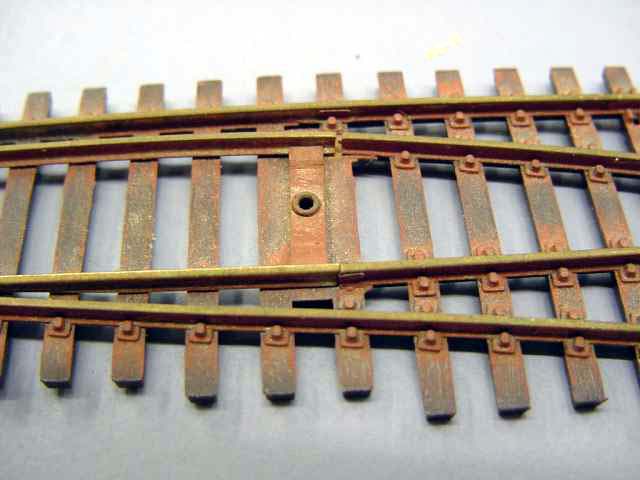

Peco – Frog

This shows how I isolate the frog. I have not shown the styrene bits glued into the gaps. At the top of the frog I have removed the short pieces of rail and moved the rail section down. This removes a possible alignment problem at a later date and means that no rail joiner / fishplate is required.

Peco – Check Gauge

While at the frog fit a piece of 15 thou (0.015″) styrene to the check rails as shown. This will allow wheels to NMRA standards to pass through the frog without the flange hitting the frog and possibly derailing.

The Insulfrog has a small piece of plastic between the two frog rails to act as insulation – it does the job very well – BUT – the wheel tread can bridge the gap. On DC this has no short term effect but long term it will cause pitting in the wheel. On DCC it will shut down the booster.

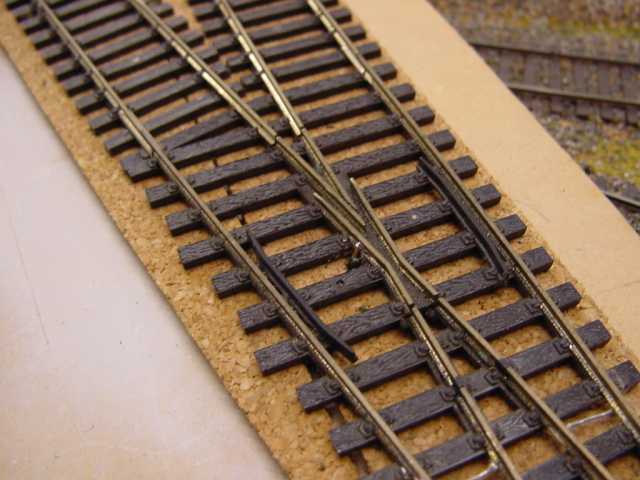

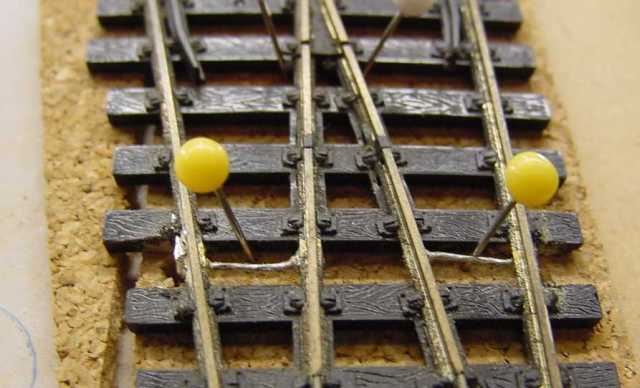

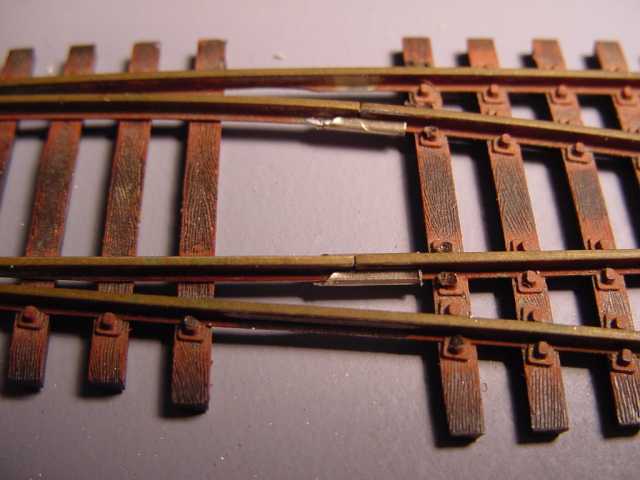

Point Rail

The turnout relies on the contact of the point rail and stock rail to get power. The yellow pins show a hard wire link between the two rails. This would normally be below the ballast or under the layout but is shown here for clarity.

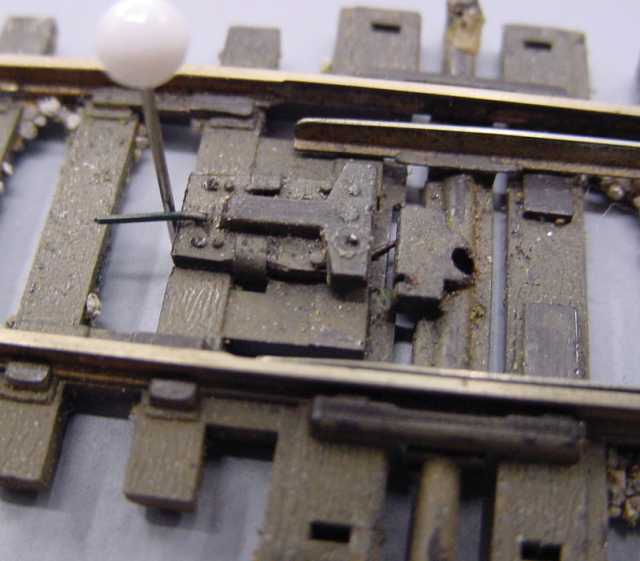

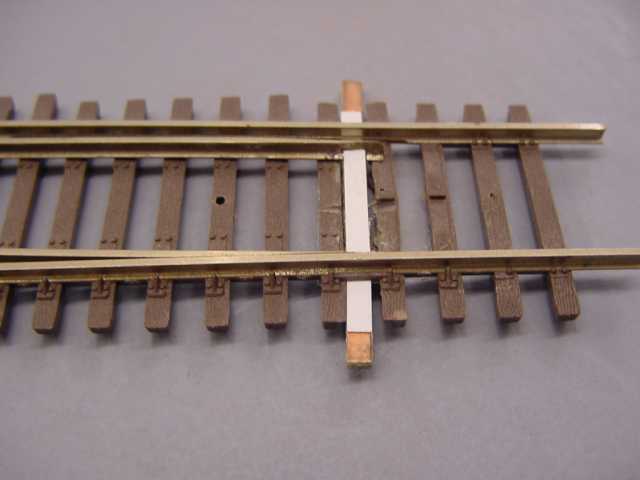

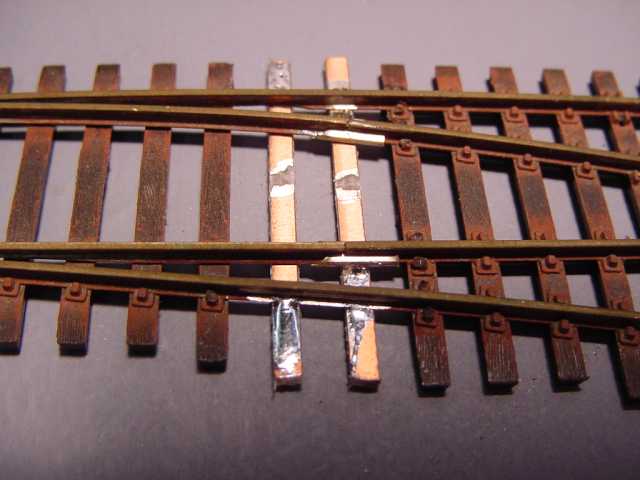

Throw Bar

This shows the throw bar with its positive locking spring (sometimes!!). The T bar to the left has a tendency to move away from the throw bar thus reducing the tension on the lock. This happens normally 33 days after you lay the turnout. The white pin shows the correct alignment for the T piece. I drill a small hole and insert a piece of wire as shown. The wire is normally cut level but I have bent it over so that you can see it. If there is not enough tension on the spring the point rail can sit away from the stock rail and cause derailments.

Micro Engineering

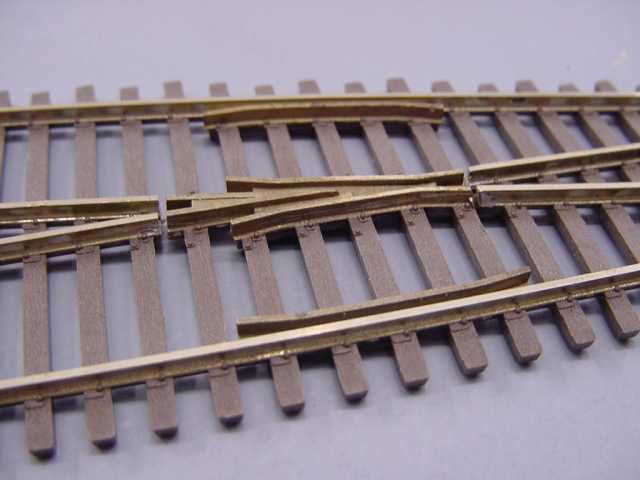

Frog Isolation

The frog is a casting on this turnout. It is easy to cut the joint between the rail and the casting. It is not so easy to solder a wire to the frog.

Point Rail

The stock rail can be wired to the point rail as shown. The contact between the rails is very poor.

Throw Bar

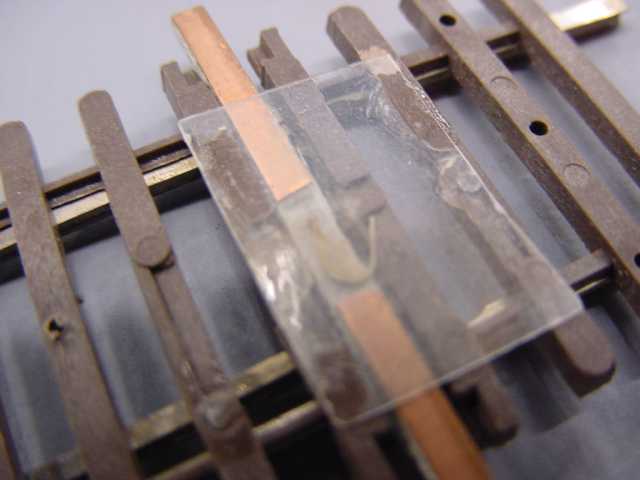

The throw bar has been replaced with a PC board tie from Clover House. The styrene is just cosmetic.

Over Centre Spring

A small piece of spring wire – 0.010 ” – has been inserted on the underside of the throw bar for positive locking. The clear styrene is to stop the spring from dropping down.

Shin O’Hara

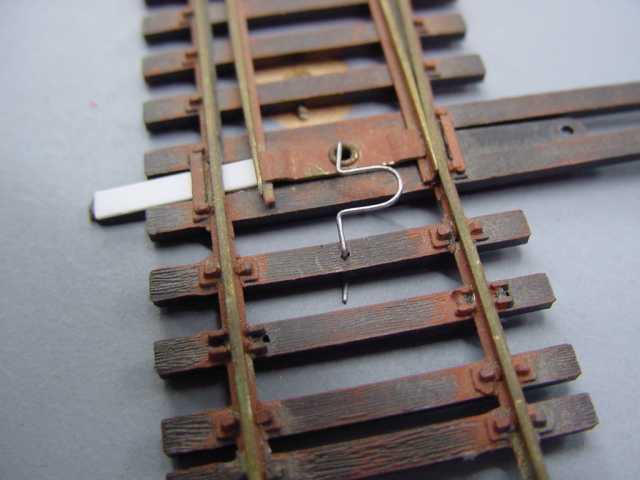

Throw Bar (Part One)

This view shows the underside of the throw bar. As you can see there is a rivet in the middle that holds the plastic to the metal bar between the point rails. This plastic is very thin and after a period of time ( normally just after you start wearing glasses) the plastic bends up in the middle. Assuming all your wheels are set to NMRA standards the fact that the two point rails are electrically joined should not cause problems, BUT, the bending of the plastic allows the point rails to rise, as much as 1.5mm (0.060″) . the rail can touch the underside of the locos or loco pickups and cause a short. Of cause, the rail rising will also cause derailments.

Throw Bar (Part Two)

This is the top side, if the turnout has already been fitted to the layout, a short term fix is to place a piece of 0.015″ styrene as shown – you will need a piece for each rail. The best fix is to replace the plastic with a PC board tie before fitting the turnout.

You can also see the centring spring for positive locking.

Point Rail Pivot

Here is the major hurdle for most people wanting to “fix” the Shin O’Hara turnout, but, it is not a hard fix. Remove the two ties under the pivot and remove the metal bar between the two rails. Replace the two ties with two pieces of PC board tie. Join the point rail to the fixed rail with HALF a rail joiner.

Fitting Rail Joiners

The rail joiner/fishplate was cut in half and then slid onto the fixed rail.

Replace the Ties

Printed Circuit Board ties have been soldered into place. An insulation gap has been cut into the centre.

Replaced Throw Bar

The throw bar has also been replaced with PCB ties stock. The centring spring has been fitted to make a more positive action of the throw bar.

All Turnout

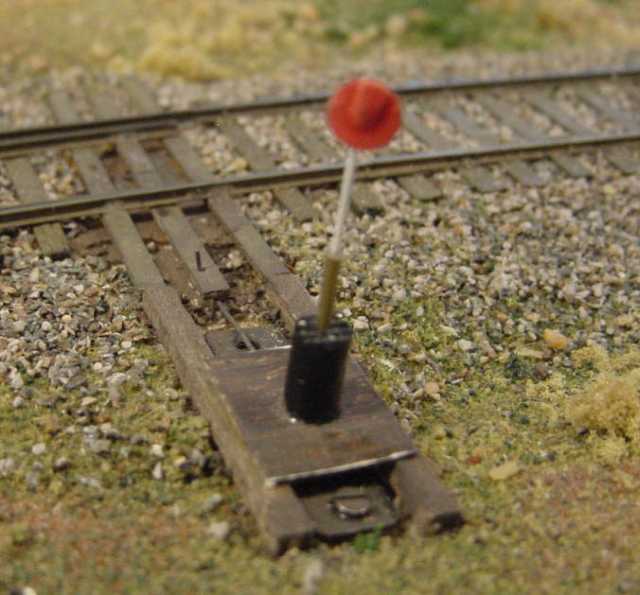

Positive Switching

This shows a positive method of mechanical and electrical switching at a low cost. The method can be used on any brand of switch and gives a positive locking of the throw bar, electrical switching of the frog, and spare contacts for signalling.

Wiring

The two stock rails (red and black) and the frog (obviously green) can be wired back to the switch. For those with an extra level of paranoia, cut the green wire in the middle and connect a lamp (1152) between the frog and the switch.

Make it Pretty

The top of the slide switch can be made to look like a switch stand with very little effort. The slide switch would cost around $1.00 each which is a little less than the cost of a turnout motor, switch for the turnout motor, wiring for the turnout motor, and a power source for the turnout motor.

Wheels in Gauge

This view shows my interpretation of a “wheel set” in gauge and having the right profile.

There should be light all around the flange and there should be a taper on the wheel tread. The wheelset shown is a Proto 2000 item and the gauge is an NMRA HO gauge. The same applies to all other gauges.

90% of turnout problems relate to wheels being out of gauge. The light around the wheel lets you know that the wheel is not being forced into the gauge. The axles are often made of nylon so the axle can flex to get the wheel into the gauge. Always be gentle.